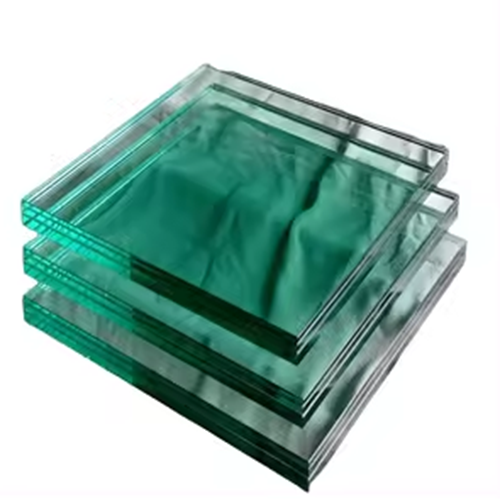

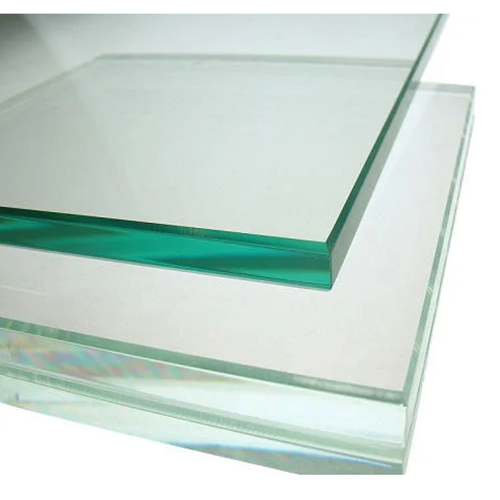

Laminated iav, muaj li ntawm ob los yog ntau dua daim iav thiab cov organic polymer intermediate zaj duab xis, vim muaj kev ruaj ntseg zoo, muaj zog tiv thaiv, suab rwb thaiv tsev thiab suab nrov txo qhov zoo, laminated iav tau ntau dua thiab dav siv hauv kev tsim kho. Raws li qhov sib txawv nruab nrab zaj duab xis, nws tuaj yeem muab faib ua PVB intermediate zaj duab xis laminated iav, SGP intermediate zaj duab xis laminated iav, EVA intermediate zaj duab xis laminated iav, xim intermediate zaj duab xis laminated iav thiab lwm yam.

Lub neej ntawm laminated iav feem ntau yog nyob ntawm cov khoom ntawm cov yeeb yaj kiab nruab nrab. Vim tias cov khoom siv TPU muaj cov khoom siv zoo heev, tiv thaiv ultraviolet, hydrolysis tsis kam, siab transparency thiab ntau yam khoom zoo heev, tau muaj kev txhawj xeeb los ntawm iav kev lag luam, TPU zaj duab xis nyob rau hauv lub tshav pob ntawm architectural iav daim ntawv thov qhov zoo maj mam highlighted, TPU intermediate zaj duab xis laminated iav maj mam nce. .

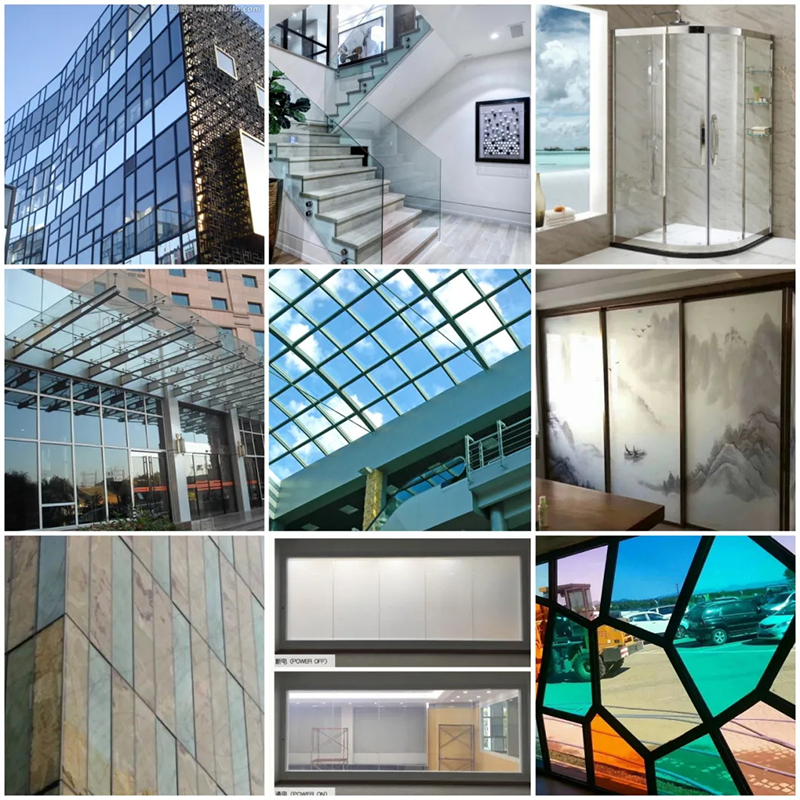

Daim ntawv thov ntawm TPU zaj duab xis nyob rau hauv daim teb ntawm architectural iav

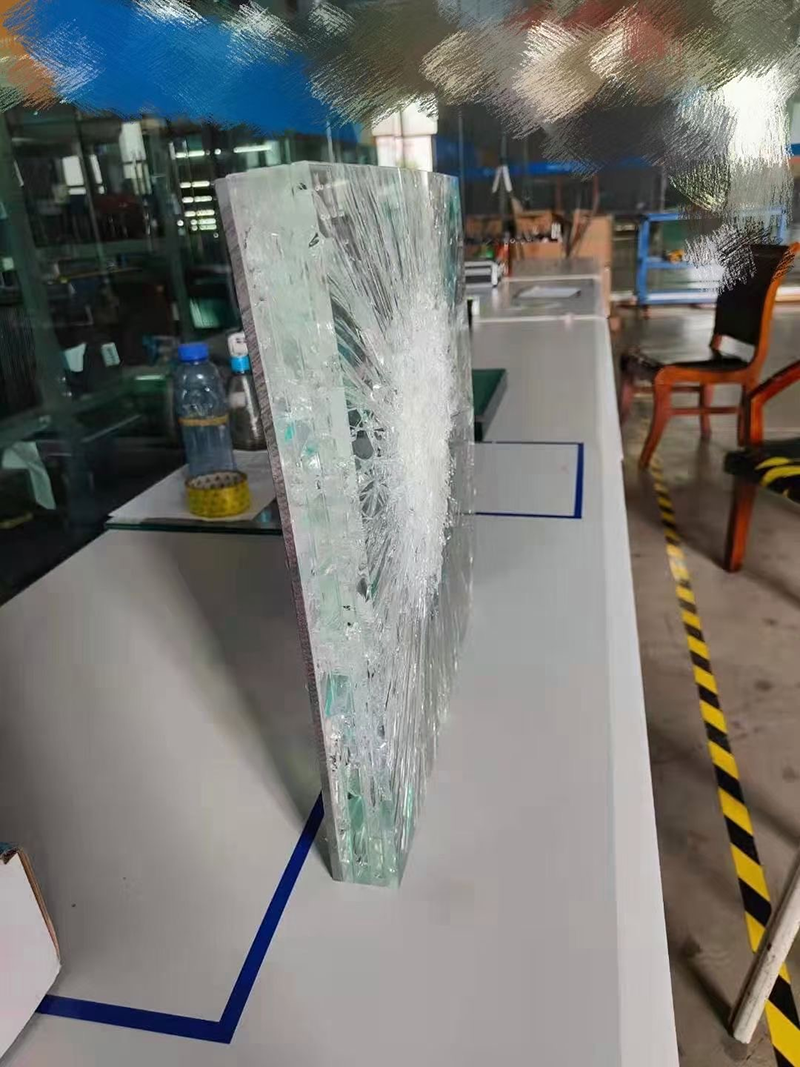

Piv nrog cov iav tsoos, laminated iav muaj kev nyab xeeb ntau dua, lub suab rwb thaiv tsev thiab kev tiv thaiv hluav taws xob ua haujlwm. Laminated iav fragments yuav daig rau zaj duab xis txawm tias lub iav tawg, zoo tiv thaiv qhov tshwm sim ntawm kev raug mob splinter thiab nkag mus rau lub caij nplooj zeeg. Feem ntau, EVA intermediate zaj duab xis laminated iav yog tsuas yog siv rau sab hauv tsev muab faib, PVB intermediate zaj duab xis laminated iav, SGP intermediate zaj duab xis laminated iav siv tau rau lub tsev tawg choj txhuas qhov rooj thiab qhov rais los yog kab hlau rhuav phab ntsa.

TPU zaj duab xis raws li cov yeeb yaj kiab nruab nrab tuaj yeem txuas rau iav thiab PC board, iav thiab acrylic board, iav thiab iav, thiab lwm yam. Piv nrog rau cov tsoos PVB intermediate zaj duab xis, SGP intermediate zaj duab xis, TPU zaj duab xis muaj cov yam ntxwv hauv qab no:

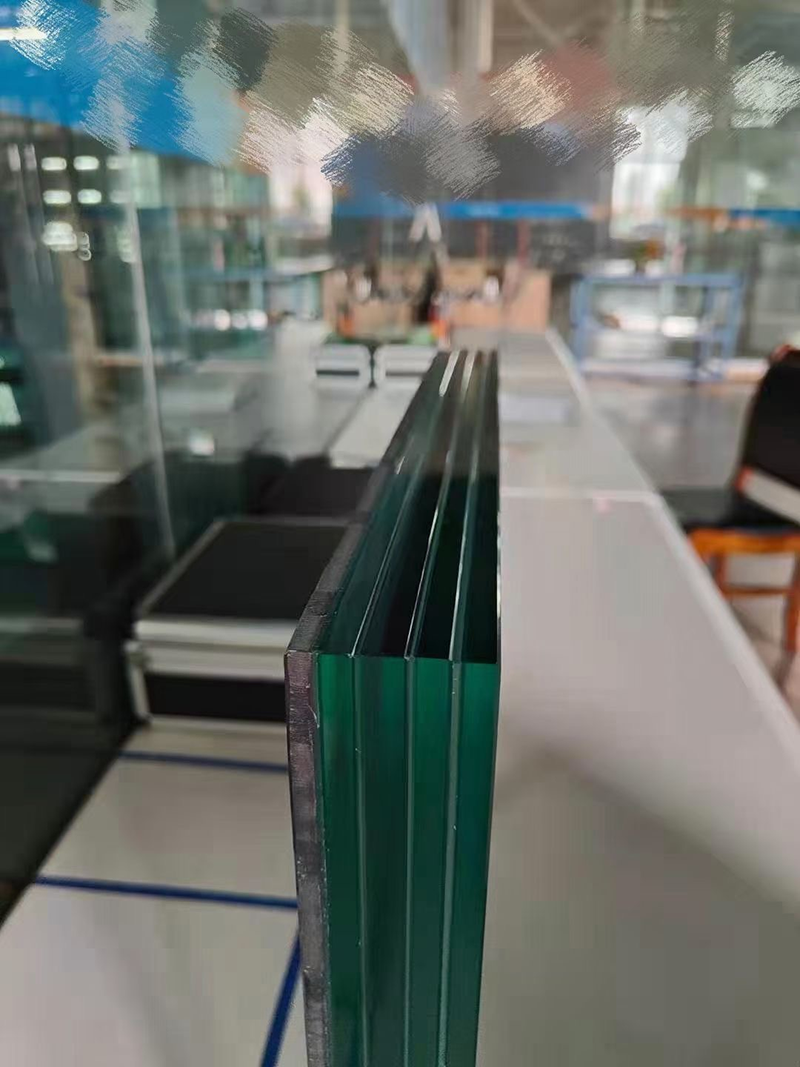

1. Kev siv zog ntau dua

TPU zaj duab xis muaj zog dua, siab dua load thiab cua siab kuj nyob rau hauv tib lub iav qauv thiab thickness.

2. Kev nyab xeeb tom qab crushing zoo dua

TPU zaj duab xis muaj zog tensile ntau dua thiab lub zog tsim kua muag, thiab cov iav laminated kuj muaj kev txhawb zog tom qab tawg.

3. Kev ua haujlwm kho qhov muag zoo dua

TPU zaj duab xis muaj lub teeb xa hluav taws xob ntau dua thiab qis pos huab, thiab muaj permeability ntau dua thiab pom cov nyhuv tom qab sib xyaw nrog iav.

Vim tias TPU intermediate zaj duab xis muaj cov khoom sib txuas ntau dua, cov khoom siv kho qhov muag thiab cov khoom siv kho qhov muag, nws tau siv dav hauv kev ua tub rog thiab pej xeem, thiab cov iav mos txwv ua los ntawm cov yeeb yaj kiab no tuaj yeem siv rau hauv dav hlau, cov tsheb loj thiab cov tsev txhab nyiaj.

TPU interfilm laminated iav muaj qhov muaj kev nyab xeeb loj thiab pom tseeb qhov zoo piv nrog cov iav zoo tib yam, thiab cov kev cai ntawm niaj hnub architecture rau iav muab qhov chaw loj loj rau TPU interfilm laminated iav. Nyob rau tib lub sijhawm, cuam tshuam los ntawm txoj cai, tag nrho cov qauv ntawm Tuam Tshoj cov khoom siv hauv tsev yog kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab TPU raws li cov khoom siv ib puag ncig yog ua raws li Tuam Tshoj txoj kev txhim kho tam sim no.

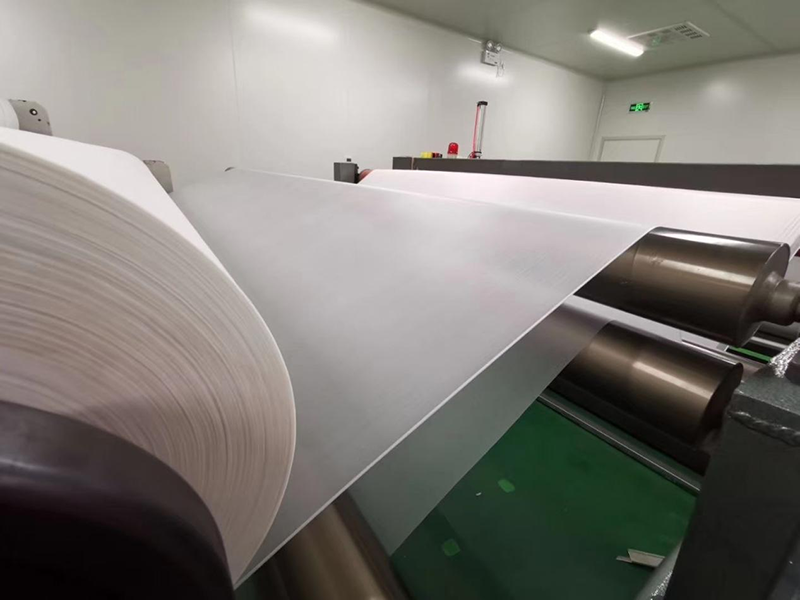

TPU zaj duab xis: ntau yam intermediate zaj duab xis rau kev sib txuas

TPU (thermoplastic polyurethane) zaj duab xis yog cov khoom siv ntau yam nrov ua cov yeeb yaj kiab nruab nrab rau kev sib txuas ntau yam substrates. Nws cov khoom tshwj xeeb ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov ntawv thov uas cov tsoos interlayers xws li PVB thiab SGP yuav tsis haum.

Ib qho txiaj ntsig tseem ceeb ntawm TPU zaj duab xis yog nws lub peev xwm los sib txuas rau ntau yam ntaub ntawv, suav nrog iav, PC boards, acrylic nplooj ntawv, thiab txawm tias lwm qhov chaw iav. Qhov no ua rau nws muaj ntau yam kev xaiv rau kev siv hauv kev lag luam xws li tsheb, kev tsim kho thiab hluav taws xob.

TPU muaj ntau qhov zoo dua li cov yeeb yaj kiab interlayer. Ua ntej, TPU zaj duab xis tau zoo heev adhesion rau cov substrates sib txawv, kom ntseeg tau tias muaj zog thiab kav ntev. Qhov no yog qhov tseem ceeb tshwj xeeb hauv cov ntawv thov uas cov khoom sib txuas yog raug rau cov neeg kho tshuab kev ntxhov siab lossis ib puag ncig yam.,

Tsis tas li ntawd, TPU cov yeeb yaj kiab muaj qhov pom tseeb zoo tshaj plaws, ua rau lawv zoo tagnrho rau cov ntawv thov uas xav tau siab pob tshab. Qhov no tshwj xeeb tshaj yog muaj txiaj ntsig zoo hauv kev lag luam tsheb, qhov twg TPU cov yeeb yaj kiab tuaj yeem siv los laminate iav los txhim kho kev nyab xeeb thiab pom kev.

Tsis tas li ntawd, TPU films muaj kev tiv thaiv zoo rau yellowing thiab degradation, kom ntseeg tau tias kev ua haujlwm ntev thiab kev zoo nkauj. Nws muaj peev xwm tswj tau nws cov kev ua tau zoo tshaj qhov kub thiab txias ntau yam kuj ua rau nws haum rau ib puag ncig sib txawv.

Tsis tas li ntawd, TPU films paub txog lawv qhov yooj yim thiab cuam tshuam, uas ntxiv dag zog rau lawv qhov tsim nyog rau daim ntawv nplaum. Nws muaj peev xwm ua tau raws li qhov chaw nkhaus thiab tiv taus cov khoom hnyav ua rau nws muaj kev ntseeg siab rau kev thov rau kev thov.

Hauv cov ntsiab lus, TPU zaj duab xis tau dhau los ua ntau yam yeeb yaj kiab nruab nrab rau kev sib txuas rau ntau yam substrates. Nws cov khoom sib xyaw tshwj xeeb, suav nrog adhesion, optical clarity, durability thiab saj zawg zog, ua rau nws yog thawj qhov kev xaiv rau cov ntawv thov uas tsoos interlayers yuav tsis xa cov kev ua tau zoo. Raws li kev lag luam txuas ntxiv mus nrhiav cov kev daws teeb meem tshiab rau kev sib tw sib tw, TPU cov yeeb yaj kiab zoo li yuav ua lub luag haujlwm tseem ceeb hauv ntau yam kev siv.

Lub sij hawm xa tuaj: Mar-21-2024