Tuam Tshoj pheej yig tus nqi Tuam Tshoj iav tshuab Spare Part, Spare xeem rau iav tshuab

Lub tuam txhab khaws cia rau lub tswv yim kev lag luam "kev tswj hwm kev tshawb fawb, kev ua tau zoo tshaj plaws thiab kev ua haujlwm zoo tshaj plaws, cov neeg siv khoom zoo tshaj plaws rau Tuam Tshoj Tus nqi pheej yig Tuam Tshoj iav tshuab Spare Part, Spare Parts rau iav tshuab, peb tuaj yeem daws peb cov neeg siv khoom teeb meem sai thiab ua tau cov txiaj ntsig rau peb cov neeg siv khoom. Rau cov neeg xav tau kev pab zoo tshaj thiab zoo heev, pls xaiv peb, ua tsaug!

Lub tuam txhab ua rau lub tswv yim kev lag luam "kev tswj hwm kev tshawb fawb, kev ua tau zoo tshaj plaws thiab kev ua tau zoo primacy, cov neeg siv khoom zoo tshaj plaws rau, Peb xav caw cov neeg siv khoom los ntawm txawv teb chaws los tham txog kev lag luam nrog peb. Peb tuaj yeem muab peb cov neeg siv khoom nrog cov khoom zoo thiab cov kev daws teeb meem thiab cov kev pabcuam zoo heev. Peb paub tseeb tias peb yuav muaj kev sib raug zoo ntawm kev sib raug zoo thiab ua rau lub neej yav tom ntej zoo rau ob tog.

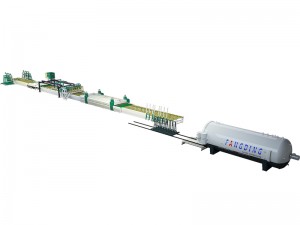

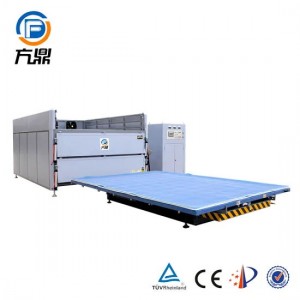

Cov iav tsis siv neeg laminating kab yog tsim los ntawm 11 qhov chaw, uas yog lub tshuab tsis siv neeg lub tshuab thauj khoom, Kev hloov pauv conveyor rau cov iav ntim, Lub Ntse iav ntxuav & ziab tshuab, Tsis siv neeg iav tso lub tshuab, Tsis siv neeg txav chaw nqus hanger, Rau cov menyuam PVB zaj duab xis khib, Hloov Hloov Conveyor rau cov iav sib dhos, Forced convection infrared pre-presser, Transition conveyor rau unloaded iav, unloading tshuab rau cov iav loj loj, thiab Forced convection autoclave. Txhawm rau ua kom tau raws li qhov sib txawv ntawm peb cov neeg siv khoom los ntawm domestic thiab txawv teb chaws, peb tuaj yeem muab tag nrho cov kab ntau lawm tsis siv neeg thiab cov kab ntau lawm semi-automatic ob qho tib si.

1. Txhua ntu ntawm kab txais PLC centralized tswj systterm, zaus tswj thiab peb HMI interface ua haujlwm.

2. Lub hom phiaj tshwj xeeb ntu yog nruab nrog encoder thiab servo lub cev muaj zog los xyuas kom cov khoom ruaj khov thiab kev ua haujlwm raug.

3. Kev ua haujlwm siab, kev txuag hluav taws xob, kev tiv thaiv ib puag ncig, suab nrov thiab lwm yam kev tswj hwm tshwj xeeb yuav tsum raug txiav txim siab nyob rau hauv tag nrho cov kab tsim.

4. Cov zaj duab xis kis tau lub tshuab txais yuav tsis siv neeg zaj duab xis tso thiab hluav taws xob zaj duab xis rov qab.6 yob ntawm yas zaj duab xis nteg, yooj yim rau kev khiav lag luam, yooj yim los hloov cov yas zaj duab xis.

5. Cov qauv ntawm cov xovxwm thawj zaug yog tsim nyog, yooj yim rau kev khiav lag luam.Lub tshuab tag nrho ua haujlwm zoo thiab muaj kev ntseeg siab, thiab yog lub hauv paus tswj hwm los ntawm chav tsev nti.Qhov chaw cua sov yog sib npaug sib npaug, thiab cov cua kub nruab nrab hauv nruab nrab-yoj infrared raj yog saws rau. cua sov. Qhov ntsuas kub yog ntsuas thiab tswj hauv cheeb tsam, thiab qhov kub siab tshaj plaws yog 250 ℃ (kho tau).

6. txais yuav txhua yam turnover unloading rooj rau unload.

7. Lub iav autoclave tau txais kev tswj hwm los ntawm PLC thiab ua haujlwm los ntawm tus txiv neej-tshuab interface kom ua tiav kev nyab xeeb, kev ntseeg tau, kev ua haujlwm siab thiab txuag hluav taws xob.

8. Tsuas yog kev saib xyuas ntawm tus neeg teb xov tooj ntawm cov chaw thau khoom thiab tshem tawm, kev ua haujlwm ntawm lwm cov kab yog tsis siv neeg, paub txog kev tsim khoom ntse, txo cov neeg ua haujlwm txaus ntshai thiab cov nqi tsim khoom.